In 1966, Dr. Yoichiro Ito and researchers at the NIH in Bethesda MD developed countercurrent chromatography (CCC). Their research development founded a versatile separation technique.

In 1983, AECS was founded. After years of consulting with pharmaceuticals and instrument design companies, the first Quattro CCC system was introduced in 1993. Since then, CCC and CPC systems have been redesigned to achieve higher reliability and the capacity to scale-up to industrial purifications.

Countercurrent chromatography (CCC) is a form of liquid chromatography. This type of chromatography is also referred to as liquid-liquid chromatography (LLC) because the separation technique does not require any solid support.

Countercurrent chromatography uses special columns because both phases are liquids, and no solid matrix is used to retain the stationary phase. The liquid stationary phase is held in place by a centrifugal force. This support-free liquid stationary phase allows for preparative separations and purifications.

Our countercurrent chromatography systems are used to separate, identify, and quantify the chemical compounds of any mixture. Countercurrent chromatography is based on the principle of partitioning liquids. Immiscible liquids are combined and then separated several times. Each individual solute is isolated based on the “partition coefficient” in the particular compound present in the solvent phase versus the diluents phase.

Countercurrent chromatography, because it is a type of liquid partition chromatography, has the advantages of operation without the use of a solid support. Therefore, all complications that arise from using a solid support are limited.

Countercurrent Chromatography systems eliminate the risk of:

- Denaturation

- Irreversible retention by solid phase

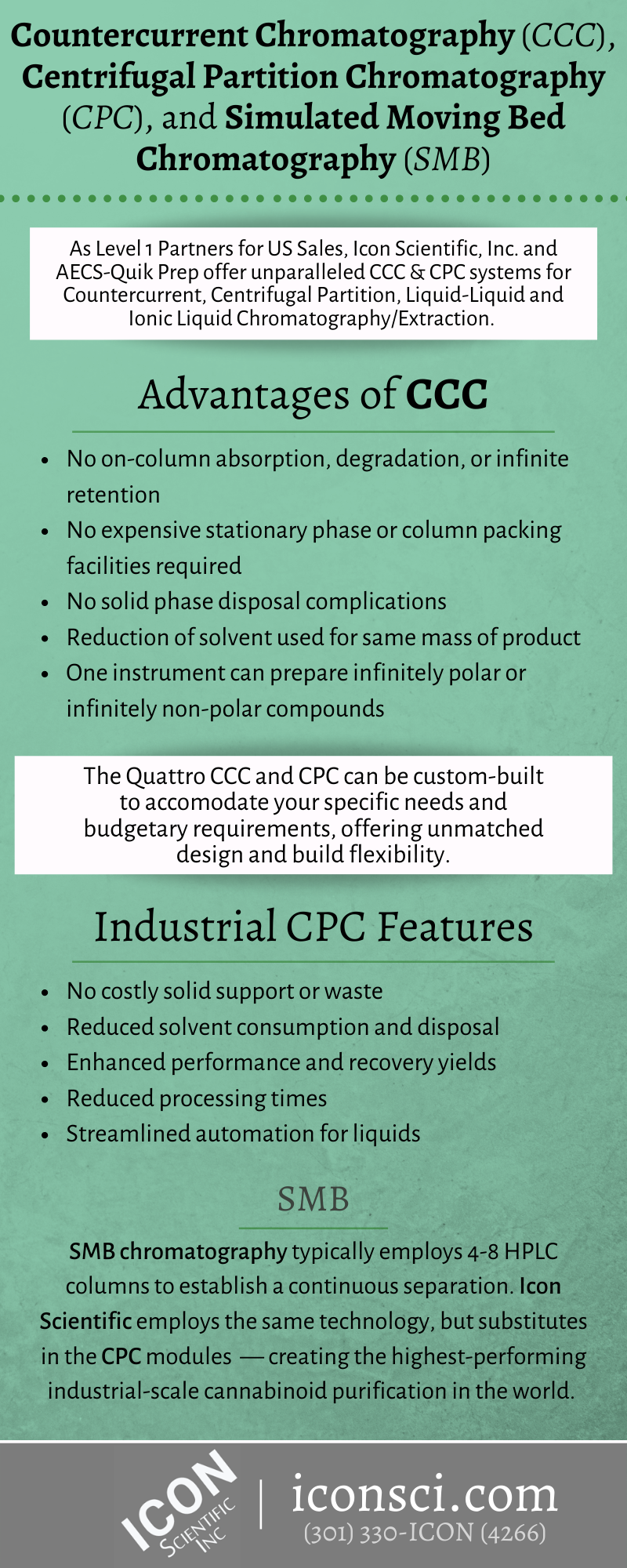

Advantages of CCC over other chromatography methods:

- No on-column absorption, degradation, or infinite retention, with generally 95% to 99% + mass balance, for mass injected to mass recovered.

- No expensive stationary phase to buy, no column packing facilities required, and no solid phase disposal issues.

- Reduction of solvent used for same mass of product. Reductions can vary, but generally, 1/2 to 1/5 of solvent may be used compared to HPLC. Greater savings are achievable if comparing to flash chromatography.

- The same instrument can prepare infinitely polar or infinitely nonpolar compounds merely by changing the biphasic solvent choice.

Many chromatography-based techniques are being used in the cannabis industry. Countercurrent chromatography is moving to the forefront. Our CCC instruments have been used for more than 10 years for cannabinoid purifications. Hydrodynamic CCC and hydrostatic CCC are also referred to as Centrifugal Partition Chromatography (CPC). Our equipment is used for cannabinoid purifications at research, process, and industrial-scale operations.

We are focused on:

- Removal of tetrahydrocannabinol (THC) to below 0.3% in broad-spectrum hemp extracts.

- Removal of state-defined contaminants from process scale purifications of THC, Cannabidiol (CBD), etc.

- Researching alternative biphasic solvent systems that do not use alkanes.

- Identifying and purifying trace medicinal cannabis noise to assist novel human and animal medicine developments.

We custom built CCC and CPC (Centrifugal Partition Chromatography) units to accommodate your specific needs, within your budget. Other competitors cannot match our design and build flexibility.

Industrial (CPC) Centrifugal Partition Chromatography features:

- No expensive solid support and no solid waste

- Reduce solvent consumption (10x) and disposal

- Higher performances (titers>99.5%)

- High recovery yields (>90%)

- Reduced processing times

- Easier automation (Only liquids)

Our line of Centrifugal Partition Chromatography systems have huge advantages:

- Unparallel robustness, For reliable (24/7/340+)

- Validation unchanged with new stationary phase each run

- Massively less prone to downtime delay if client induced blockage

Centrifugal Partition Chromatography is known for its dynamic range of scalability, from lab to industrial scale. CPC has the ability to accommodate chemically complex samples with undissolved particulates.

CPC (Centrifugal Partition Chromatography) and SMB (Simulated Moving Bed Chromatography)

Simulated moving bed chromatography usually employs 4 to 8 HPLC columns to establish a continuous Chromatographic separation, which radically increases the separation efficiency as compared to traditional batch chromatography. We employ the same concept and technology but substitute the process CPC (Centrifugal Partition Chromatography) modules in place of the HPLC columns. This creates the highest performance industrial-scale purification of cannabinoids in the world.

Icon Scientific can configure multiple 12-liter HPCPC’S (High Performance Centrifugal Partition Chromatography), 3 to 8 units in a Simulated Moving Bed Chromatography format for continuous operation.

Our systems are world leaders in countercurrent, Centrifugal Partition, Liquid-Liquid, Ionic Liquid Chromatography/ Extraction. Our prices include installation and on-site training in your laboratory.

Call us today: 301-330-4266