Liquid chromatography (LC) is a separation technique used to separate particles of a compound in a solvent mixture. This allows full analysis of each individual particle.

HPLC pumps deliver a consistent flow and constant pressure of liquid for a chemical reaction. HPLC pumps are used for process applications and/or the production of a product.

ICON Scientific’s vast line of pumps all offer precision, reproducibility and ruggedness. Our high pressure dosing pumps are highly accurate and reliable two-piston pumps for pharmaceutical and chemical applications as well as research and method development. Pumps are used for a wide range of tasks in chemical, food and pharmaceutical industries. Pump heads are available in various materials, stainless steel, titanium, and PEEK, Hastelloy C or ceramic. Maximum flow rates for the pump heads range from 100 ml/min, 250 ml/min, 500 ml/min to 1000 ml/min. Pumps can be controlled either by keypad, PLC control or software control.

All preparative dosing pumps are a two piston reciprocating design which assures maximum reproducibility of flow, lack of pulsation and extreme ruggedness.

Jet mixing technology has outstanding results for small and large scale pharmaceutical production of vaccine lipid nanoparticles. Small desktop devices are available, as well as complete LNP skids for pharmaceutical researchers.

IJM (impingement jets mixing) skids are available for high flow production of nanoparticles (LNP). These systems can be configured with up to 8 parallel mixing units. Each unit consists of two pumps delivering lipid and API streams, one jet mixer and two flowmeters. All skids are constructed of a stainless steel frame, and built on casters to be suitable for CIP cleaning procedures in pharmaceutical production. We offer customizable solutions to meet our customers specifications. HPLC pumps have now become critically important in the fight against COVID-19. HPLC pumps are being used to produce liquid nanoparticles (LNP) for the production of the mRNA vaccines. ICON Scientific offers a line of HPLC pumps that are extremely suitable for liquid nanoparticle production.

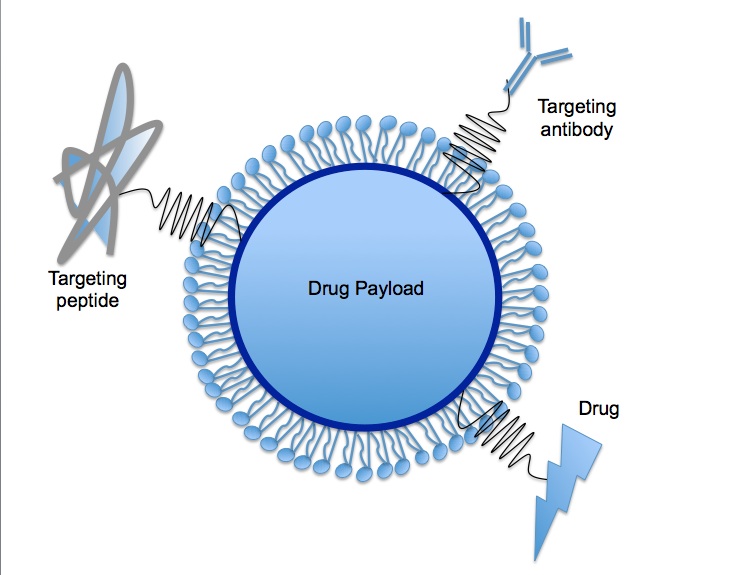

Lipid Nanoparticle

Lipid nanoparticles (LNP) are the delivery form of choice for mRNA based vaccine development and production. LNPs encapsulate and protect the sensitive active ingredient allowing it to enter the target cells in the human body. COVID-19 vaccines are the first large-scale use of lipid nanoparticles (LNP) and mRNA in vaccine history. LNPs can form a stable basis for the administration of RNA, mRNA, siRNA, or DNA based APIs. These active ingredients optimize delivery to the target cells. This is a promising development in medicine.

Lipid nanoparticle (LNP) systems are used to encapsulate mRNA with lipids. The mRNA needs to be protected with lipid production to prevent degradation and to increase integration in the bodies cells.

ICON Scientific’s HPLC experience and sophisticated pumping technology is critically important in enabling us to provide superior LNP solutions.

Very precise pumping technology is extremely critical for high-quality lipid nanoparticle (LNP) production systems. Our systems offer fast, precise pumping technology, reliable switching of liquids, constant control of parameters using software and a flow meter. The software executes control function when critical changes in the flow rate are recorded. We have an elaborate mixing technology.

Successful COVID-19 vaccine technology has created significant interest in using mRNA vaccines in place of traditional vaccines. Traditional subunit vaccines have been used successfully but they do not induce cellular immunity. Cellular immunity is needed to eradicate the intracellular pathogen reservoir in viral infections. Live attenuated vaccines are the most potent in activating the immune system, both cellular and humoral immunity. The problem is these vaccines cause considerable safety concerns. In immunosuppressed patients there’s always a concern about administering a live vaccine. Attenuated pathogens, on rare occasions, could revert to the pathogenic form and cause disease.

mRNA vaccines seem to combine the advantages of live attenuated vaccines and traditional subunit vaccines without the associated risks of live attenuated or DNA vaccines.

DNA and mRNA vaccines are similar but different. The main difference is the target location for delivery of the oligonucleotides. Oligonucleotides (oligos) are short single strands of synthetic DNA or RNA. DNA therapeutics need to reach the nucleus, while mRNA therapeutics target the cytosol. mRNA therapeutics are easier to deliver because they do not need to cross a nuclear membrane. mRNA does not integrate itself or alter the genome. Cytosolic mRNA has no interaction with the genome. Essentially, mRNA represents minimal genetic information, and is only expressed until the mRNA has been degraded. mRNA has the ability to encode multiple proteins having very difficult chemical and physical properties, without affecting its physiochemical properties.

In conclusion, mRNA synthesis and purification are not only fast, but easy to manufacture and are low in cost in comparison to other vaccine technologies. Today, lipid nanoparticles are the chosen vectors for in vivo RNA delivery.

Our wide portfolio of dosing pumps are optimized to meet your needs. The resulting integration of our pumps and mass flow controllers ensures optimal conditions for lipid nanoparticle formation. We have quickly adapted to meet the needs of our pharmaceutical partners.

In addition to offering hardware and software needed to implement lipid nanoparticles (LNP) scale-up and production, ICON Scientific has over 40 years experience in HPLC pumping systems. We are subject matter experts. Use our experience to your advantage!