When it comes to designing and manufacturing robotics solutions, there’s no company more dedicated, experienced and knowledgeable in the scientific industry than HTA. We offer an extensive collection of analyzer front-ends and sample preparation workstations designed to fit applications in analytical chemistry, life sciences and clinical laboratories; this even includes GC, LC and ICP autosamplers. HTA manufactures in Italy under a certified UNI EN ISO 9001:2015 and 13485:2016 quality management systems.

Key Features

EASY TO USE

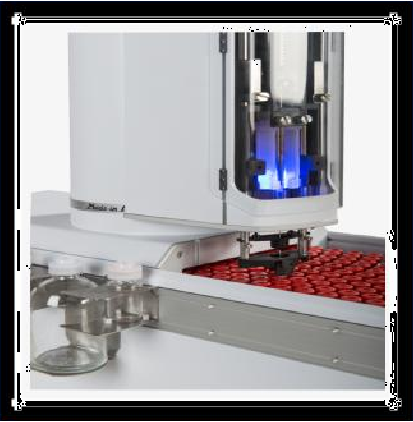

Easy to use, easy to install and easy to service. We believe in a “robust by design” approach: HT4000L – based on cutting edge technologies and DFX design – well incarnates this philosophy making itself the ideal instrument for installation in any scenario.

Full loop is performed with very high accuracy values, while partial loop also allows sample saving. The variable fill

speed and the viscosity delay allow a wide range of sample viscosities; programmable sampling depth assures high sample recovery capacity. All the routine operations such as analysis start, sample loading and extra wash can be managed by its dedicated keypad. Set your method once using the complimentary HTA Autosampler Manager, then you just need to load samples and press START: experience a seamless integration with your Chromatography Data System.

LARGE SAMPLE CAPACITY

HT4000L can handle up to 176 2ml-vials per run or it can work with different kinds of sample vessels. Inject samples out of vials (2/4/6/10/20/40 ml), test tubes, tube blocks or plates.

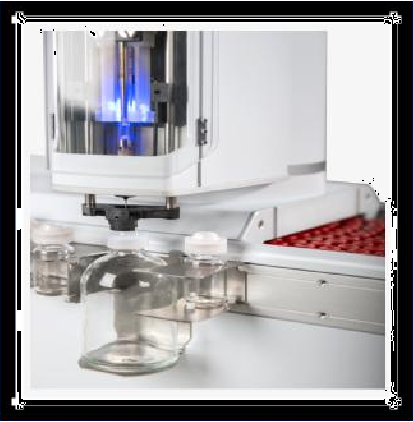

Save on consumables avoiding needs for sample reformatting. Choose from standard racks or enquire for a custom design: custom racks pay for themselves in a few weeks. Furthermore, racks are easily interchangeable in order to allow quick switching across multiple configurations.No compromise in terms of solvent capacity and solvent selection: we have a wide capacity to accommodate the most challenging requests. Solvents can be located in vials (for accurate micro- or nano-volume dispensing) or in bottles (for large-volume dispensing). Additional solvents modules may also be implemented in the field in case requirements change over the time.No need for solvent degassing. While some autosamplers require a devoted degasser line or to degas offline wash solvent on each bottle refill, we do not. Enjoy HT4000L: less system requirement, less pain, less troubleshooting!

APPLICATION VERSATILITY

HT4000L fits all liquid chromatography systems. It is able to look after the widest range of applications including analytical, prep, UHPLC, IC, nano, LC/ MS… and many more.

Within the standard configuration the autosampler is equipped with an automatic 6-port 2-way injection valve for analytical applications. However, a wide selection of valves for inert or extended pressure applications are also available as per special injection ports for applications where no valve is needed.

MODULAR AND SCALABLE

A wide range of accessories can be sourced and added in the field at any time. Contact your sales representative about your application requirement. Too many options? Don’t worry; you don’t pay for features you don’t need. We provide your LC autosampler at the best possible price; at the time your needs change you can add optional accessories to perform the new tasks without the hassle of buying a new autosampler. Your investment is future proof!

LAB AUTOMATION READY

HT4000L can fully automate your sample prep. It can work as a standard HPLC autosampler. However you may want to delegate some sample preparation tasks: HT4000L can take care of them as no standard autosampler has been able to assist.

Dilution, precolumn derivatisation, pH spiking and internal standard addition are available within the standard

version: no extra cost required. These operations can be performed in place or in an empty vial by sample dispatching.

If standard sample preparation capabilities are not enough, get the HTAPREP option. Using HTAPREP – lab automation software – you can add support to complex and custom autosampler methods. Design your own methods by Drag&Drop of autosampler functions (e.g. draw, dispense, mix, inject…) and start processing samples with the smart processing engine that allows you to optimise productivity and reagent consumption.

Endless possibilities: any sample preparation procedure or complex sample introduction become available: check the brochure of HT4000A (off-line version of HT4000L) to discover more.

UHPLC READY

UHPLC applications require an extended pressure range and a reduced amount of injected sample. HT4000L is optimised for such requirements and can be supplied with an UHPLC injection valve or can be upgraded in the field at a later time.Also in this configuration HT4000L features extraordinary analytical performance with the highest reliability.

LARGE-VOLUME CAPABILITY

The only real autosampler choice in the market for large-volume applications.We provide you with everything you need for your large-volume applications: large sample vessel support, large injections up to 10ml, large solvent capacity, large bore size injection valve (or injection port) for real and complete automation.

BIOCOMPATIBLE

To handle more complex samples and to assure covering a wider pH range, inert flow path valves are available. No need to compromise when it comes to running metal-sensitive samples or corrosive solvents/buffers.

Furthermore, biocompatible applications can take advantage of the double wash step capability: as pre- and post-wash solvent in addition to A, B… F solvents you can also choose a combination of A+B, A+C…. F+E solvents for superior analytical performance (carryover adverse!).

COOLING

The Cooling Module offers the capability to maintain samples at a controlled temperature. The cooling option upgrade can be performed in the field in a very short time: you don’t need to make a decision about cooling at the time the autosampler is sourced!

Technical Specifications

General features

| Syringe volume: | Standard: 100, 250, 500ml and 1, 2.5, 10mlNano-Volume Opt.: 5, 10, 25, 100m |

|---|---|

| Tray capacity (standard): | 176 vials, 2ml (1 removable rack), 96 vials, 4ml (1 removable rack)54 vials, 6/10/20ml (1 removable rack)3, 96-well plates (1 removable rack)Custom trays available |

| Tray capacity (cooled): | 121 vials, 2ml42 vials, 6/10/20ml2 96-well plates |

| Maintenance: | Preventive counters available |

| Electrical control: | LAN and TTL |

Analytical performance

| RSD: | Full loop: ≤ 0.25% (typically 0.15%), Partial loop: ≤ 0.5% |

|---|---|

| Linearity (r): | ≥ 0.9999 |

| Carry over2: | ≤ 0.05% (with standard wash),typically ≤ 0.01% (with int/ext needle wash) |

Wash (Pre & Post Injection)

| Washing cycle: | up to 15 (Mode: every injection/sample/step) |

|---|---|

| Reagents: | up to 2 different reagents for wash function |

| Stator wash: | programmable |

Filling

| Sample volume: | as low as step of 1ml3 |

|---|---|

| Air volume: | as low as step of 1ml3 |

| Filling speed: | 1-100ml /sec3 |

| Viscosity delay: | 0-25s |

| Bubble elimination: | up to 15 pull up strokes |

Injection

| Injection mode: | Full Loop, Partial Loop |

|---|---|

| Flush Volume: | programmable |

| Injection speed: | 1-500ml /sec3 |

| Analysis time: | 0-999min |

| Wait time between consecutive injections: | as low as 12sec4 |

Diluition, derivatization, pH spiking, IS addiction

| Reagent addiction: | step of 1ml3; up to 3 different reagents |

|---|---|

| Mixing cycle: | programmable |

| Intermediate wash cycle: | up to 15 |

| Reaction time: | 0-100 minutes (0.1 minutes step) |

Physical features

| Dimensions (WxHxD): | 310x705x690mm |

|---|---|

| Weight: | 15kg |

| Power supply: | 100-240±10%Vac; 50-60Hz; 55W |

Cooling Module

| Technology: | Peltier |

|---|---|

| Temperature range conditioning: | from 4°C to 40°C |

| Temperature accuracy: | +/-1°C (typically +/-0.5°C) between the vials |

| Cooling capacity: | about 20°C below the RT (on the vial) |

| Working ambient temperature: | 25°C +/-10°C |

| Weight: | about 5kg |

| Power supply: | 100-240±10%Vac; 50-60Hz; 120W |

| Field installation: | yes |

Additional modules:

Among the most popular modules:

- Barcode reader (BCR)

- Flow Cell

- Gripper for vial displacement

- Internal/external needle washing

- Sample Capacity Extension

- Vial Heater/ Reaction Cell

- Vortex