standard version, 1240 bar

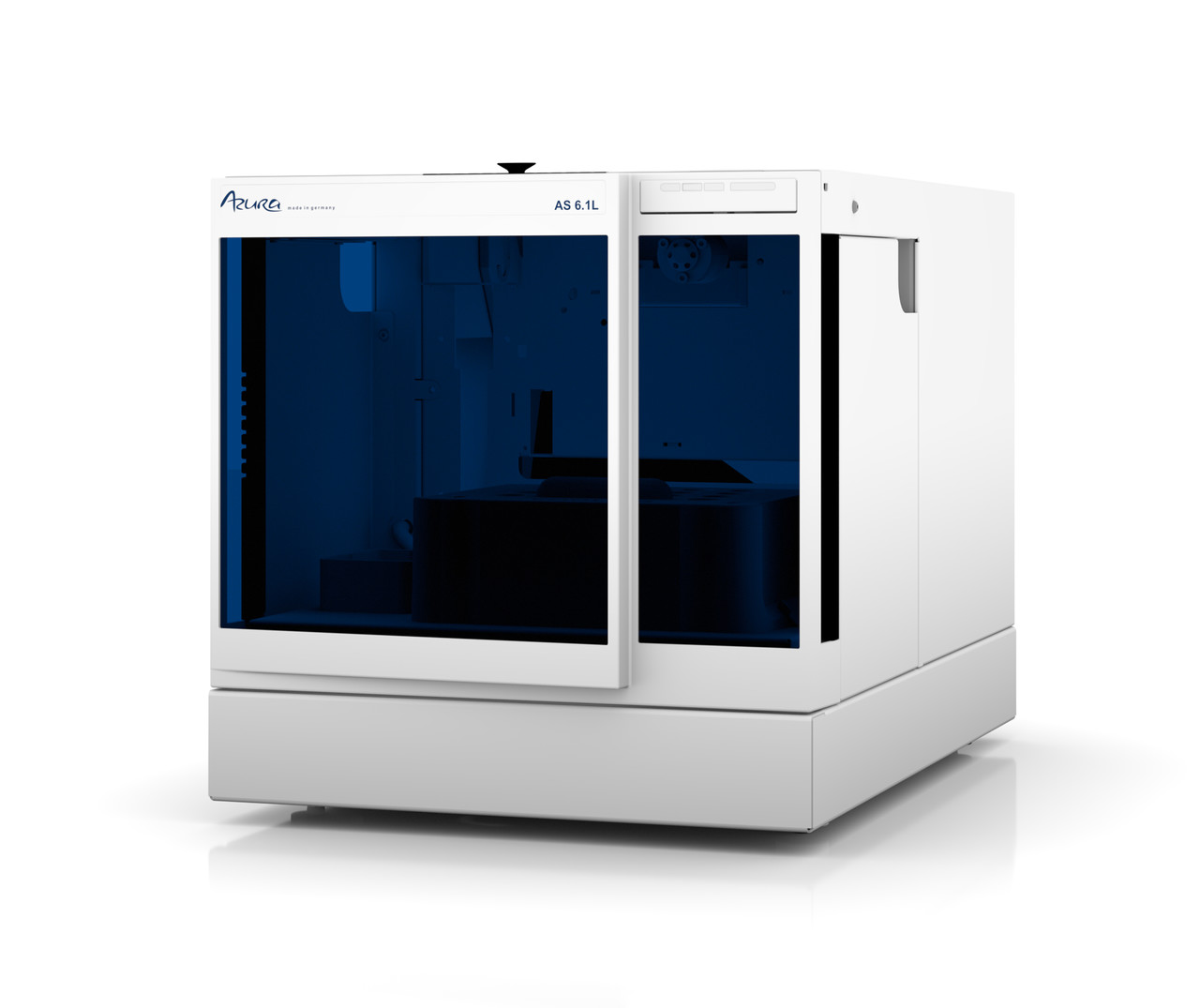

The Autosampler AS 6.1L can inject from up to 768 positions when equipped with microtiter plates (either high or low formats) or from up to 108 standard 2 ml sample vials. Sample carryover is significantly minimized thanks to a highly-effective interior and exterior needle wash procedure. This autosampler is also fast and flexible: one complete sample injection cycle takes less than one minute, including needle wash. Three different injection modes are supported; “full loop filling” (highest precision and reproducibility), “partial loop filling” (variable volumes, e.g. for dilution series) and “µl pickup” (loss-free injection of extremely small sample volumes), allowing the user to optimize sample usage. The headspace pressure function prevents bubbles from forming in the vial during sample uptake. Precolumn derivatization is supported. For high-pressure injections of up to 1240 bar, the autosampler is equipped with a so-called ILD™ valve (Intermediate Loop Decompression). This valve consists of a rotor-stator combination and includes a central port for depressurizing. For highpressure applications, the sample loop is depressurized prior to receiving the sample. This way, the sample is not diluted with solvent. Because the valve is switched extremely fast, pressure spikes are reduced. Analyses are more precise and wear of the column is reduced.

Technical Data

| Autosampler Flow Path |

Analytical |

| Maximum back pressure |

1240 bar |

| Vial/plate dimensions |

max. plate/vial height: 47 mm (incl. septa or capmat) |

| Injection volume range |

0.1 µl – 10 ml depending on sample loop |

| Sample loop |

10 µl |

| Dispenser syringe |

250 µl |

| Headspace pressure |

built-in compressor, only for sample vials with septum |

| Switching time inj. valve |

< 100 ms |

| Piercing needle precision |

± 0.6 mm |

| Sample tray cooling |

none |

| Vial detection |

missing vial/well plate detection by sensor |

| Needle wash |

programmable: wash between injections and wash between vials |

| Wetted materials |

Tefzel® (ETFE), Glass, Teflon® (PTFE), Kel-F® (PCTFE), stainless steel, PEEK

|

| Injection modes |

full loop filling, partial loop filling and microliter pickup; PASA™ (pressure-assisted sample aspiration) |

| Injection precision |

RSD (Relative Standard Deviation):full loop filling: <0.3%partial loop injection at injection volumes>5 µl: <0.5%microliter pickup at injections>5 µl: <1.0% |

| Sample carryover |

< 0.05 % with needle washing |

| Injections per vial |

max. 9 injections |

| Injection cycle time |

minimum 7 s from the same vial, 14 s from different vials;< 60 s for>100 µl sample injection in all injection modes, incl. 300 µl needle wash |

| Analysis time |

max. 9 h, 59 min, 59 s |

| Inputs |

2 programmable TTL inputs (next injection, freeze, stop) |

| Outputs |

1 programmable relay output (inject marker, auxiliary, alarm) |

| Control |

Ethernet (LAN) |

| Interfaces |

LAN, analog |

| Ambient conditions |

temperature range: 10–40 °C; 50–104 °F air humidity: 20 – 80% |

| Power supply |

95–240 V AC |

| Dimensions |

377 x 300 x 510 mm (W x H x D) |

| Weight |

30 kg |

-

AZURA Autosampler AS 6.1L User Manual EN (V6821)

-

AZURA Autosampler AS 6.1L User Manual EN (V6821)

-

List of supported devices in chromatography data systems EN (V1663)

Device support in KNAUER CDS / KNAUER device support in 3rd party software